Rigid Foam Boards: The Complete Homeowner’s Guide to High-Performance Insulation

When it comes to insulating your home effectively, rigid foam boards stand out as one of the most versatile and efficient options available. Whether you’re planning a new construction project, renovating an existing space, or simply looking to improve your home’s energy efficiency, understanding rigid foam insulation can help you make informed decisions that save money and enhance comfort for years to come.

What Are Rigid Foam Boards?

Rigid foam boards are solid panels of insulation made from various types of plastic foam materials. Unlike fluffy fiberglass batts or loose-fill insulation, these boards maintain their shape and provide consistent insulation value throughout their lifespan. They’re manufactured in standard sizes, typically 4 feet by 8 feet, though other dimensions are available, and come in various thicknesses ranging from half an inch to several inches.

The beauty of rigid foam lies in its exceptional insulating properties packed into a relatively thin profile. This makes it particularly valuable in situations where space is at a premium or where you need maximum insulation value without adding excessive bulk to your walls, roof, or foundation.

Types of Rigid Foam Insulation

Understanding the different types of rigid foam boards helps you select the right product for your specific application. Each type has unique characteristics, strengths, and ideal use cases.

Expanded Polystyrene (EPS)

EPS is the most economical option among rigid foam boards. You might recognize it as the white beaded foam commonly used in packaging materials, though building-grade EPS is denser and more durable. It offers decent insulation value at around R-4 per inch of thickness and resists moisture reasonably well. EPS works particularly well for below-grade applications like basement walls and under-slab insulation. Its affordability makes it attractive for budget-conscious projects, though it provides less insulation per inch compared to other foam types.

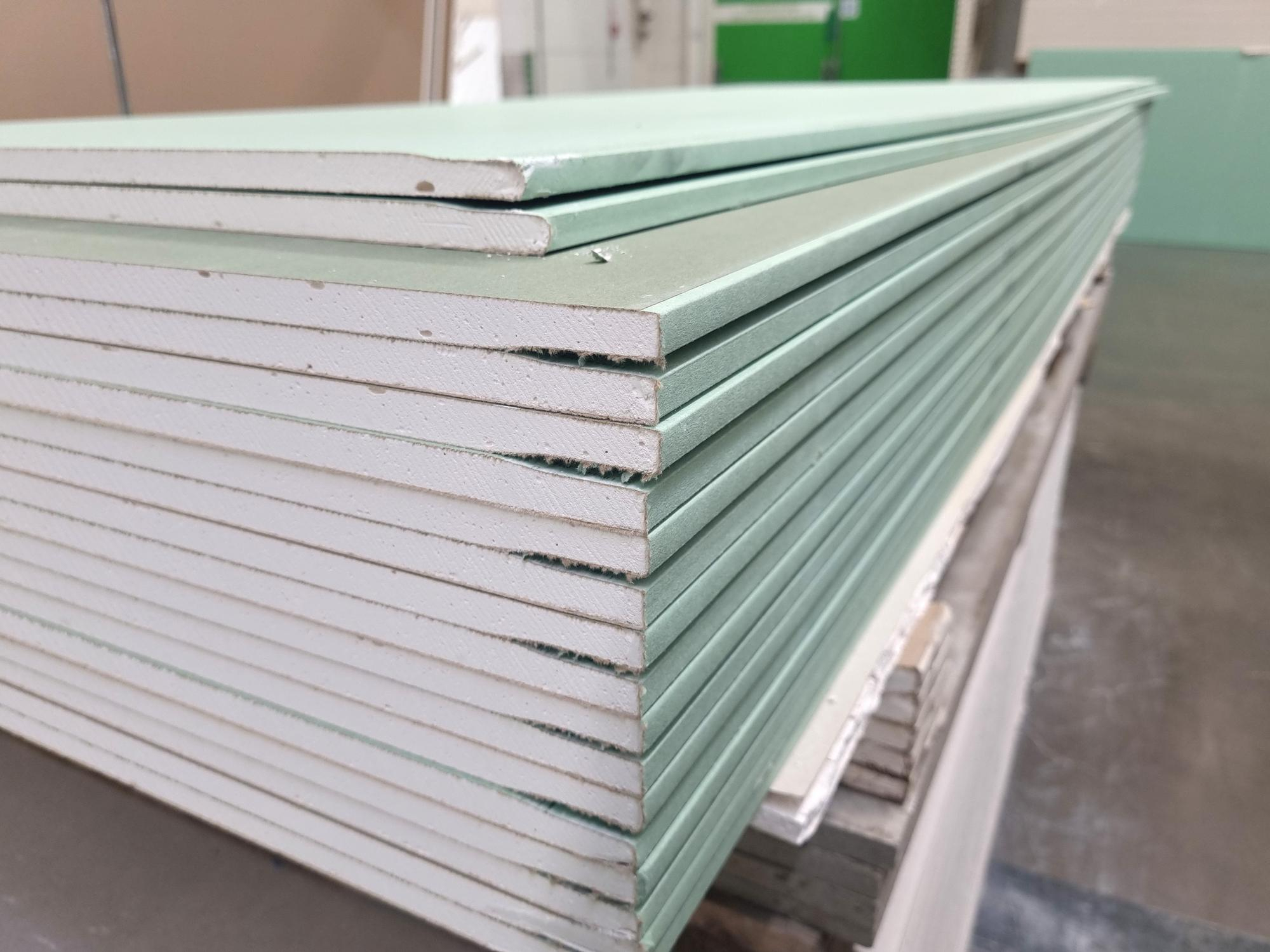

Extruded Polystyrene (XPS)

XPS boards, often recognized by their distinctive blue, pink, or green colors depending on the manufacturer, offer superior performance compared to EPS. With an R-value of approximately R-5 per inch, XPS provides better insulation in a thinner profile. These boards feature a smooth skin on both sides and a uniform closed-cell structure that makes them exceptionally resistant to moisture absorption. This moisture resistance makes XPS an excellent choice for areas prone to dampness, including foundation walls, beneath concrete slabs, and exterior wall sheathing.

Polyisocyanurate (Polyiso)

Polyiso represents the premium end of rigid foam insulation, delivering the highest R-value at around R-6 to R-6.5 per inch. These boards typically feature foil facings on one or both sides, which serve dual purposes: they contain the blowing agents used during manufacturing and provide a radiant barrier that further enhances insulation performance. Polyiso excels in above-grade applications such as roof insulation, wall sheathing, and cathedral ceilings. However, its performance can decrease in extremely cold temperatures, making it less ideal for exterior applications in very cold climates.

Ready to Achieve Top-Tier Efficiency with Rigid Foam Boards?

Rigid foam delivers the highest R-value per inch, unbeatable moisture resistance, and seamless continuous insulation — perfect for basements, exteriors, and retrofits. When paired with NYSERDA programs and Inflation Reduction Act rebates, New York homeowners are getting high-performance rigid foam upgrades with thousands in rebates or even fully covered at no upfront cost. Lock in comfort and savings for decades.

Where to Use Rigid Foam Boards

The versatility of rigid foam insulation makes it suitable for numerous applications throughout your home. Understanding proper placement helps maximize its benefits.

Foundation and Basement Walls

Rigid foam excels at insulating foundation walls, both inside and outside. When installed on the exterior of foundation walls, it protects the waterproofing membrane and keeps the foundation warmer, reducing freeze-thaw cycles that can cause cracking. Interior applications work well too, creating a thermal break between cold concrete and living spaces. This application significantly reduces heat loss and prevents condensation issues common in basements.

Exterior Wall Sheathing

Installing rigid foam over wall studs and beneath siding creates a continuous insulation layer that dramatically improves whole-wall R-value. This approach addresses thermal bridging, where heat escapes through wood studs, which conduct temperature better than insulation. The continuous insulation provided by rigid foam can reduce heating and cooling costs substantially while making your home more comfortable year-round.

Roof and Attic Applications

Rigid foam performs exceptionally well in roof assemblies, particularly in cathedral ceilings where cavity space is limited. It can be installed above roof decking, creating an unvented roof assembly that eliminates the need for soffit and ridge vents while providing superior insulation. Some homeowners also use rigid foam to insulate attic hatches or as part of a comprehensive attic insulation strategy.

Under-Slab Insulation

Placing rigid foam beneath concrete slabs prevents heat loss to the ground and eliminates cold floors. This application is particularly valuable in homes with radiant floor heating, as it directs heat upward into living spaces rather than allowing it to dissipate into the earth. Even in homes without radiant heating, under-slab insulation significantly improves comfort and efficiency.

Installation Considerations and Best Practices

Proper installation of rigid foam boards requires attention to detail and adherence to building codes. While some homeowners tackle foam board installation themselves, complex applications often benefit from professional expertise.

Cutting and Fitting

Rigid foam cuts easily with a utility knife, circular saw, or specialized foam cutter. Making precise cuts ensures tight fits that minimize gaps where air could infiltrate. Any gaps between boards or around penetrations should be sealed with appropriate foam-compatible caulk or expanding spray foam to maintain the thermal barrier’s integrity.

Fastening Methods

Attachment methods vary depending on the application. Below-grade installations might use construction adhesive, while above-grade applications often require mechanical fasteners with large washers to prevent the fastener heads from pulling through the foam. Some applications combine adhesive and mechanical fasteners for maximum holding power.

Vapor and Air Barriers

Understanding moisture management is crucial when working with rigid foam. Some foam types, particularly foil-faced polyiso and XPS, act as vapor retarders themselves. In such cases, you need to carefully consider the overall wall or roof assembly to avoid trapping moisture. Working with a building professional or energy consultant ensures your insulation strategy manages moisture properly while maximizing energy efficiency.

Energy Savings and Financial Benefits

Investing in rigid foam insulation delivers tangible financial returns through reduced energy consumption. Homes with proper rigid foam insulation typically see heating and cooling cost reductions of 20 to 40 percent compared to poorly insulated structures. These savings accumulate year after year, often recouping the initial investment within several years.

Many utility companies and government programs offer rebates and incentives for improving home insulation. NYSERDA rebate programs provide financial assistance to New York homeowners who upgrade their insulation, making energy-efficient improvements more affordable. These programs recognize that better insulation reduces overall energy demand, benefiting both individual homeowners and the broader electrical grid.

Ready to Achieve Top-Tier Efficiency with Rigid Foam Boards?

Rigid foam delivers the highest R-value per inch, unbeatable moisture resistance, and seamless continuous insulation — perfect for basements, exteriors, and retrofits. When paired with NYSERDA programs and Inflation Reduction Act rebates, New York homeowners are getting high-performance rigid foam upgrades with thousands in rebates or even fully covered at no upfront cost. Lock in comfort and savings for decades.

Comparing Rigid Foam to Other Insulation Types

While rigid foam offers numerous advantages, it’s worth understanding how it compares to other insulation materials. Various insulation types and their applications each have unique strengths and ideal use cases. Fiberglass batts cost less initially but provide lower R-value per inch and don’t create the air barrier that rigid foam does. Spray foam offers excellent air sealing but costs more and requires professional installation. Mineral wool provides good fire resistance but weighs more than rigid foam.

The right choice depends on your specific situation, budget, and performance goals. Many homes benefit from a combination approach, using different insulation types where each performs best.

Environmental Considerations

Modern rigid foam boards have evolved significantly from earlier versions that used harmful blowing agents. Today’s products increasingly use more environmentally friendly alternatives, though some environmental concerns remain regarding the manufacturing process and eventual disposal. Recycling options for rigid foam exist but aren’t universally available.

Balancing these considerations against the long-term energy savings rigid foam provides requires thoughtful evaluation. The substantial reduction in heating and cooling energy consumption over the product’s lifespan often outweighs the environmental impact of manufacturing and disposal, particularly when the foam remains in place for decades.

Making Your Decision

Rigid foam boards represent a proven, effective insulation solution that can dramatically improve your home’s comfort and efficiency. Whether you’re insulating a foundation, upgrading exterior walls, or tackling a roof project, rigid foam offers performance that’s hard to match with other materials. The key lies in selecting the appropriate foam type for your application, ensuring proper installation, and integrating it into a comprehensive approach to home energy efficiency.

Taking the time to understand your options, consulting with qualified professionals, and potentially leveraging available rebate programs sets you up for success. Your investment in quality insulation pays dividends in comfort, lower utility bills, and increased home value for many years to come.